AEREON - Steam Assist Flares

From Custom Flares and VCUs for Onshore & Offshore

Steam assisted flares are flares designed to dispose of heavier hydrocarbon gases which have a tendency to smoke. In order to prevent smoke formation, steam is injected into the waste stream using peripheral steam rings, center stream spargers and/or inner induction tubes. Steam flares are used in applications where high pressure steam is available on site. Steam flares are typically found in downstream applications where high efficiency combustion of heavy hydrocarbons is required. AEREON supplies both internal steam ring (SteaMax-i) and external steam ring (SteaMax-e) designs for its steam assisted flares.

-

Most popular related searches

Product Overview

Steam assisted flares are designed to dispose of heavier waste gases which hav e a greater tendency to smoke. In order to prevent incomplete combustion, steam is injected into the waste stream using peripheral steam rings, center steam spargers, and/or inner induction tubes. The injection of steam has two principal effects:

- High-pressure steam flow causes turbulence in the waste stream which improves mixing and therefore improves combustion efficiency.

- Additional air is induced into the waste gas providing the oxygen necessary for augmented smokeless capacity.

Steam flares are typically used in applications where the customer has high-pressure steam available on site.

Advantages

- Low maintenance costs

- High smokeless capacity due to steam injection

- Stable, reliable combustion due to flame retention ring

- High smokeless flow rate

- Longer tip life due to steam cooling effect

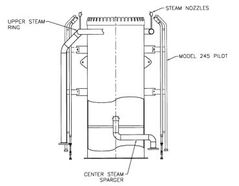

SA MODEL

- External steam injection stabilizes the flame and entrains air, ensuring efficient combustion

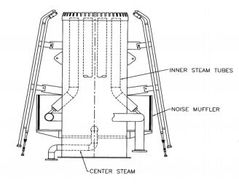

SAI MODEL

- Internal induction tubes with venturi inlets for improved air inspiration

- Higher smokeless capacity

- Reduced noise at a given capacity

Principle Applications

- Petrochemical processing

- Petroleum refining

Design Features

- High pressure steam must be available

- High alloy material construction in the heat affected zone prevents induction tubes, rings, and spargers from warping and cracking.

Primary or secondary steam injection through:

- Peripheral ring (SA Model)

- Center sparger (SA & SAI Models)

- Internal induction tubes (SAI Model)

Flame Retention Ring to stabilize combustion

- Low noise design with the use of external noise muffler (SAI Model)

Specifications

DIMENSIONS

- Length: 10’-0” (3)

- Diameter: 4”-84” (0.1-2.13m)

- Upper Section Incolloy 800H (options): 304,316,310 SS,

MATERIALS

- Lower Section: Carbon Steel

- Retention Ring: 304.316.310SS

- Dynamic Seal: 304SS

- Steam Ring: 321SS

- Center Sparger: 321SS

- Internal induction Tubes: 304,316,310SS

Customer reviews

No reviews were found for AEREON - Steam Assist Flares. Be the first to review!